Category: Construction Maintenance Electrician

4 Common Residential Electrical Flaws Examined for Those Who Want to Become An Electrician

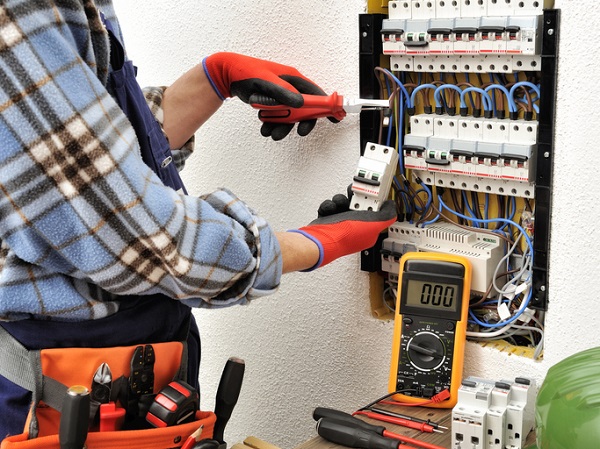

December 02, 2020 Electricians called into homes to work on a specific problem have often reported discovering additional electrical issues, some of them potentially hazardous. Many electrical issues in the home are caused by work done by unqualified people, or by homeowners trying to save a few bucks with DIY home reno jobs. Electrical defects are also frequently found in older homes, where outdated fuse boxes, outlets, and wiring are often ill-equipped to supply the power demands of the many modern electrical devices used in the average household of today.

Electricians called into homes to work on a specific problem have often reported discovering additional electrical issues, some of them potentially hazardous. Many electrical issues in the home are caused by work done by unqualified people, or by homeowners trying to save a few bucks with DIY home reno jobs. Electrical defects are also frequently found in older homes, where outdated fuse boxes, outlets, and wiring are often ill-equipped to supply the power demands of the many modern electrical devices used in the average household of today.

While some of these problems may appear to have harmless symptoms, many of them left unattended have the potential to cause tragic house fires or electrocutions. With that in mind, here are a few of the most common—and potentially hazardous—electrical flaws pros should look out for in people’s homes.

1. Plugs Fitting Loosely in Receptacles

Many homeowners may have noticed an outlet or two in the home where the prongs of electrical devices don’t seem to fit as firmly as they should. This problem is usually caused by the contacts of the outlet receptacle becoming worn over time, causing the plug to sit loosely in the outlet, with the metal prongs of the plug often partially exposed.

Electricity will usually still flow in this circumstance, posing a high fire risk due to loose contacts causing electrical arcing. Any flammable object near the compromised outlet is at risk of igniting, such as bed skirts, curtains, or even an accumulation of dust. While the fire risk is high in this circumstance, the repair work is simple, requiring a quick, low-cost receptacle replacement.

2. An Absence of GFCIs

Ground fault circuit interrupters (GFCIs) are built-in outlet fixtures designed to prevent hazardous electrical shocks. A person with electrician training should be aware of this design, which is usually found in wet regions of the home where electrocution is more likely, such as bathrooms, the kitchen sink area, and outdoor connections. On an inspection, the electrician should look out for GFCIs in these areas of the home, and recommend replacements to older outlet coverings for optimized safety.

3. Overlamping

Even students of electrician school may have at one time or another made the common homeowner error of using a lightbulb with higher wattage than a light fixture is designed to accommodate. It may seem like a small problem, but the mistake rates as a fire risk due to the extreme overheating that will eventually scorch the light socket.

Not only is the socket at risk of melting, but the heat can also burn its way through the fixture’s wires, causing the arcing phenomenon that’s usually at the root of so many electrical fires in the home. Even if the homeowner is lucky enough to avoid a fire from a longer period of overlamping, the light fixture will usually be permanently damaged. To prevent all risk, homeowners should be advised to always ensure they’re using a bulb with the recommended level of wattage limits labeled on the light fixture.

4. Ungrounded Connections

Students of electrician school will need to understand the concept of grounding, which is a safety feature design added to electrical appliances, devices, and outlets to safely discharge an excess of electricity in the event of a wiring defect. If currents escape from the safety of the wiring unit in such defects, connections without a grounding system leave those loose currents at risk of flowing through nearby objects instead. This poses a damage risk to the device in question, and an electrocution risk to the person using it. As a standard safety measure, electricians should highly advise any homeowner with insufficient grounding connections and wiring to invest in an updated installation.

Are you interested in taking professional training to become an electrician?

Contact North American Trade Schools today for more information on its specialized program!

5 Facts About Residential Wiring for Those Interested in Electrical Training

September 29, 2020

If you’re considering becoming an electrician, you might be surprised by the variety of standards and regulations set in place for wiring systems in residences such as homes and cottages. Homes contain a variety of appliances and safety features which require electrical wiring. Hydro One, Ontario’s electricity provider, has a number of specifications in place for how they are to be installed within the home.

Here are five things to consider with regards to residential wiring.

Wiring Sizes May Be Different for Residences

For residences, common wire sizes may be different from other types of buildings. The American Wire Gauge Number (AWG) serves as the standard measurement of a wire’s diameter. Residences typically use four kinds of AWG wire sizes, with different amp circuit numbers for each: 8 (40 amp circuits), 10 (30), 12 (20), and 14 (15). The No. 8 AWG is often used for loads like electric ranges. No. 10 is used for loads needing electricity, such as dryers and electric water heaters. No. 12 serves loads like kitchen counter receptacles (e.g. appliances like microwaves). And No. 14 works best with loads such as lights (eg. lamps), switches, smaller appliances, and receptacles. Electrical box sizes may also vary, but this depends on several factors. These include the mounting of switches or receptacles, how many wire conductors are present, how many are in use, and the conductors’ sizes.

Many Different Appliances Require Electrical Installation in a Home

The home has a variety of appliances which have different electrical installation needs. The oven, refrigerator, dishwasher, counter spaces, built-in microwave ovens (and possibly more) all require consideration when planning for residential wiring. These appliances typically require their own, separate receptacle, from an entirely different circuit. As those with electrician training may know, any receptacle with 15 to 20 amp circuits must not only be marked, but tamper-resistant. This is because inserting any conductive object that is not a plug into the receptacle can cause electric shock. However, Hydro regulations state that, if a stationary appliance’s receptacle is a minimum of two metres above ground and/or out of reach, tamper resistance is not necessary. Prior to installation, be sure to mark on your floor plan where these appliances—and their corresponding receptacles—are located.

Different Rooms Within the Home Require Different Wiring Configurations

If you’ve completed maintenance electrician training, you will need to follow many requirements when working on residential homes. Hydro One has a set of requirements for each room in the house to ensure safe living conditions for residents. For one, each room must be equipped with a light controlled by a light switch. Two lights controlled by a three-way wall switch—one for the bottom and the top each—is required for any stairway containing a minimum of four stairs. Keep in mind that, on any two-wire branch circuit, 12 outlets are allowed at maximum. This includes receptacles and lights. Range receptacles must also be installed in the home with their receptacles marked on the floor plan.

Those With Electrician Training Should Plan to Install Smoke Alarms

Smoke alarms are an important and necessary safety feature for homes. They are required to be installed on each of the home’s floors, and a battery backup should also be present. Additionally, there should be one in each bedroom and an additional alarm in hallways attached to them. These smoke alarms must all be interconnected and should operate at 120 volts. Either a branch circuit with a receptacle/lightning combination or an unswitched lighting branch circuit can be used for these alarms.

Service Size May Depend on the Requirements of the Home

Typically, homes should have a distribution panel containing 24 circuits, and a service size of at least 100 amps. When calculating the service size, take into account the kilowatt demand. There are multiple factors which help to determine this, such as electric heating, the area of the floor, and appliances, among other loads that may be present. Although the service size should be larger if a home requires greater amounts of heating, most homes with a minimum 100-amp service size should be able to maintain both their typical electrical loads and electrical heating of up to 10 kW.

Do you want to become a construction electrician?

Check out North American Trade Schools’ programs today!

The Most Sustainable Construction Materials for Those in Construction School

September 08, 2020

Plenty of work has been done over the last few years to make the construction of necessary buildings more sustainable. That includes taking a look at the construction materials themselves. There are different definitions of sustainability in terms of construction materials. It could refer to products that are locally sourced, how resilient a product is, or how much energy it takes to produce it.

Some professionals are looking at material sustainability as a concept that considers all the energy required to extract a material, produce it, and transport it. They also look at its appropriateness for the environment, the rate at which it degrades, and how often it needs to be replaced. Some construction professionals are also moving towards sustainability by incorporating recycled materials. Read on for a few examples of sustainable materials!

Bamboo Could Dominate the Construction Trades

Bamboo is a construction material with a lot of potential. It can be used in walls, flooring, or furniture, and its benefit is that it is extremely durable and strong. It has a greater compressive strength than even bricks or concrete. Its high strength-to-weight ratio means that it is relatively lightweight and takes less energy to transport than many other materials.

Bamboo is a perennial grass and can be found on several continents. Currently, it is mostly grown in South America and Asia. As a grass, its extremely quick rate of self-generation helps its sustainability. It continues to spread and grow without the need to replant it after harvesting it. Professionals with a career in construction should be aware of one potential downside to using bamboo: it requires treatment to make it resistant to insects and rotting.

Sheep’s Wool Is A Natural Construction Material

Sheep’s wool is a material that has been used for all kinds of things for hundreds of years. These days, it can still be beneficial for the construction industry. Sheep’s wool is naturally insulating. And, while it’ll still need extra treatment to make it properly safe with regards to fire risks, it is a material with a naturally high ignition temperature. As a result, it can be an energy-efficient insulator used in walls, ceilings, and attics.

One of the sustainable benefits of sheep’s wool is that it has similar properties to mineral wool or glass wool but requires less energy to produce. It is, of course, naturally regenerating. One of the potential downsides to using this material is that it requires treatment to prevent the infiltration of insects and fungi.

Cork Doesn’t Have a Significant Environmental Impact

Cork comes from the tree bark of the cork oak. After construction school, professionals can use this material as flooring or sub-flooring. It’s very flexible and resilient, a good thermal insulator, and efficient at absorbing noises and shocks, making it an effective construction material.

The benefit of this material is that it’s sourced entirely from natural sources. The cork oak will continue to grow and reproduce the material after it is extracted from it, making it a sustainable resource to use within the construction industry.

Do you want to make your entry into the construction trades?

Contact North American Trade Schools for more information!

Considering Pre-Apprentice Maintenance Electrician Training? Here’s a Day in the Life of an Electrical Technician

July 21, 20203 Steps to Starting Your Own Business after Construction School

April 07, 2020

If you are business-minded with an entrepreneurial spirit, you might be considering starting your own business after graduating from a construction program. Business owners can enjoy a flexible schedule, ample learning opportunities, and competitive remuneration.

However, starting a business is far from simple. Even the best construction worker in the world will need to conduct market research, have a basic understanding of finance and accounting, and learn about law and marketing.

Read on to find out more about what it takes to start your own business after construction training.

Step 1: Do Your Research

Before even thinking about launching your own business, you will need to conduct in-depth market research to establish demand and rates. Is there demand for another construction business in your area? How much are people paying on average for typical projects?

If you have any friends or acquaintances working in the industry, make sure to ask them for any insights. You could also do some research online and use social media to identify your main competitors, or even conduct surveys and organize small focus groups.

Use this research to form your business plan and identify your unique selling point (USP). What can you offer customers that no one else can? Is it a better price point? Or expertise in one particular area? Whatever it is, use it to your advantage in a career in construction.

Step 2: Prepare an In-Depth Business Plan for Your Career in Construction

Once you’ve done your research, you’re ready to write your business plan. Make it as detailed as possible,marking out your goals for each month and including estimated annual turnover and gross profits. This will be particularly useful if you need to apply for funding from a financial institution.

This should also give you an idea of how much money you’ll need to get started. After studying at construction school, you should have a good idea of all the tools and equipment you’ll need to work as an independent construction worker.

Calculate how much you’ll need to invest in these, as well as in vehicles, marketing, and software. It can take a while for any new business to start making money, so make sure you have a cushion for the first few months.

You’ll also need to decide who you want to work for. Do you want to work for residential property owners or businesses? Are you looking for small jobs or bigger, long-term projects? As well as this, how many staff will you need to hire? Or will you choose to work with contractors? Thinking about these things early on will help you form a clearer picture in your mind of what your business will look like, and what you need to do to get it off the ground.

Step 3: Check the Paperwork

As with any new business, you will need to make sure that you’ve completed all of the necessary paperwork correctly. You will need to register your business for an EIN, and have all the right licenses and permits. You will also need to get insurance to protect yourself and your business.

If you’re concerned about legalities or taxes, it might be a good idea to hire a lawyer or an accountant. You could be the best construction worker in the world, but if you can’t take care of the administration of your business, it won’t go far!

Do you want to learn more about construction trades?

Contact North American Trade Schools for more information!

4 Things Electrician School Students Should Know About Roughing In Electrical Wiring

February 04, 2020

If you want to become an electrician, this is a tool you’ll definitely want under your belt.

Roughing in electrical wiring is something any construction electrician will want to get right, regardless of which part of a house they’re working on. After the framing and initial wiring has been done, you’ll want to make sure the rough-in — the part of the process where the cables are pulled through framing members and studs before going into boxes — is completed before ceilings and walls are closed.

There’s an art to doing it the right way, and any aspiring electrician can do well to keep a few tips in mind. Here are some tips for getting roughing in electrical wiring right if you’re studying to become an electrician.

Before Pulling Wires, Be Sure to Straighten Them Out

Straightening out wires will make the process of pulling cables through holes much easier. To do this, straighten the cable between your forefinger and thumb while you’re walking along its length.

After pulling it through the holes, push it back so that there’s still some slack, just in case the cable gets cut too short and more length is necessary. Also, make sure cable protection plates are installed before pulling anything, and that they are drilled close to the edge of a stud. They will need to be set back at least 1 to 1 ¼ inches away from the edge of a wood-framing part.

Picking the Right Electrical Box Will Go a Long Way

During your electrician career in construction, you will have a choice of electrical boxes to use for different projects.The most common ones are made of fiberglass or plastic.

Depending on the size of the wire gauge, they can be used for large appliances, living spaces, bathrooms or kitchens. Plastic boxes are typically less expensive than fiberglass models, although they aren’t as tough.

Be sure to pick a box with a minimum volume of 20 cubic inches. Larger boxes will make the wiring process easier, so you should pick one large in size that is made with the right materials for the project.

If you’re working on a ceiling fan, you’ll need a special type of electrical box attached with a brace, so that it can make the fan more stable and absorb its vibrations.

Make Sure All Holes are Well-Aligned and Straight When Drilling

You’ll want to be sure that holes are straight and symmetrical in height, so that pulling cables is as easy as possible. If they are pulled at varying heights or angles, it can cause cables to snag on sharper edges.

Once ¾ inch holes are pierced into the framing members above the boxes, centre the part on the stud before bracing the drill. Use your thigh to put pressure on it to make drilling the studs easier.

Ensure the holes are consistently kept at the same height, so that you can more easily fish cable through. You’ll be able to pull cables and drill holes once all boxes are nailed correctly.

After Electrician School, Don’t Over-Bend Any Cables

While bending cables, make sure they are not bent at more than a radius of 2½ inches. You can avoid over-bending them if you drill holes at a range of 8 to 12 inches above or below boxes, so that the cable can go upwards or downwards into them.

This is important for students at electrician school to remember, because the conductors and sheathing can be weakened if the cable is bent incorrectly or too sharply, resulting in a fire hazard.

In any case, it’s important to remember that you’ll need to be as gentle as possible when wiring, to avoid damaging the conductors, as they will carry the electricity. Conductors are also vulnerable to stress and fatigue from overbending, or bends that are too sharp.

Want to get your electrician diploma?

Contact North American Trade Schools for more information!

4 Tips for First-Year Apprentices Working Towards Electrician Certification

January 22, 2020

After you complete a pre-apprenticeship program you can seek out an electrician apprenticeship, where you get paid while learning on the job. In Ontario it can take up to five years to complete an apprenticeship during which you will learn the tools of the trade from professionals. An apprenticeship also includes some more time in the classroom and is a necessary step to becoming a licensed electrician.

Before you start your apprenticeship, you may have an idea of what it will be like, but there are a few points that may help you adjust to on-the-job training. Also, depending on which province you apprentice in, there might be loans to buy tools as you start and grants to support you during your classroom hours. In the meantime, here are a few tips to help you during your first year as an apprentice.

1. Ask Questions

While it is true that you are doing a job and you are getting paid, an apprenticeship is still training and it is a great time to ask questions. Professionals know that you are learning to become a maintenance electrician and should be prepared to explain tools and procedures to you. This may be as simple as asking “what’s next?” and “why?” Electricians have experiential and sometimes highly specialized knowledge that goes beyond the classroom. This is why they may have special insight and it is worth asking for as much information as you can get.

2. Record Your Hours

When you are on your way to electrician certification it will be necessary to record your hours and ensure that they are counted toward the completion of your apprenticeship. The same way you will have to keep up to date with electrical codes and regulations as an electrician, you should stay up to date on your progress as an apprentice. Not only is this necessary, it also helps you keep track of how much you’ve learned.

3. Stay Healthy

You will get a sense of the physical demands in the first year of your apprenticeship and many electricians say it is important to stay in good shape. Electrician work can involve a lot of movement, stretching and lifting. You will be able to work longer and better in your career if you are healthy. The first year of your apprenticeship is a great time to work exercise into your routine, and make sure you are having nutritious meals.

4. If You Want to Become a Maintenance Electrician, Take Your Work Seriously

Electricians are highly respected skilled trades people and play an important role in construction and maintenance. When you begin your apprenticeship, remember that you have a big responsibility. It is important to do basic things like show up on time for jobs, but it is also important to remember that you are responsible for maintaining safety standards in whatever setting you work. The more seriously you take your work during the first year, the more you’ll develop good habits in your career that can help you land additional work in the future.

Want to know more about maintenance electrician training?

Visit North American Trade Schools today!

Exterior Wall Components for Electrician Training and Beyond

December 13, 2019

When you study construction maintenance for electricians, you will have the opportunity to apply what you learn in the classroom to hands-on training. This will include working on skill sets for commercial, industrial and residential electricity, analyzing and preparing machine controls, and building an exterior wall, among other things.

Exterior building walls, on first glance, may just appear to be what you see from the outside. When you look at a building you may see materials like brick, cement, siding, or shingles. However, the construction of an exterior wall that is fit for its environment is a complex process that requires a lot of attention to detail and design. Here are a few important points about exterior wall components.

A Brief Introduction to Components for Electrician Training

During your electrician training it will become clear that understanding a building layout and how walls are constructed is important for maintaining electrical systems. The exterior wall assembly in particular helps protect the interior of a building from outside elements. This not only refers to providing shelter for people, but also keeping systems within the building running properly.

Here is a quick introduction to the components of exterior wall assembly:

- Exterior cladding: this layer is chosen based on environmental conditions as well as aesthetics. It is the first, but not most important, defence against weather.

- Air barrier, also known as air paper or house wrap: this is a weather resistant layer that allows moisture to escape.

- Vapour control layer: moisture can build up in the exterior wall assembly without this component so it is typically required by building codes and regulations.

- Insulation: this supports interior temperature control.

- Structural element: this is the load bearing component (or components) that distributes weight and pressure to the structural frame of a building.

Interface Conditions

After you are introduced to the functions of each component of an exterior wall assembly it is important to understand how each component affects the whole. Essentially, the assembly must be able to control and mitigate moisture and protect the interior, including its electrical systems. The ways in which the components of the wall assembly are separated, joined and installed, are referred to as the interface conditions. For example, elements like flashing and end dams prevent excess rain from entering the dry zone of the assembly and may be necessary around windows, or where the wall meets the roof.

Examples of Common Materials

There are many standard materials for exterior wall assemblies that you might be familiar with even before you start maintenance electrician training. For example, Tyvek and Typar are two of the most common polyethylene air barriers. They let water vapour out, but eliminate exterior moisture, thus protecting wiring that may otherwise be vulnerable to moisture. Like tarpaper, another common air barrier, they can be damaged by UV rays.

For the exterior cladding some of the most common materials are cedar shingles, vinyl, cement board, stucco, brick, and a few others. Vinyl or steel siding can be applied directly to air paper. However, if you are using brick or stucco, the interface conditions dictate that a layer of rain screen siding may be required. At the very inside, the most common material is drywall. Overall, your expertise on each of these elements will be required as you work with building plans.

Want to become a maintenance electrician?

Find out how from the North American Trade Schools!

Infographic: 4 Awesome Benefits of Trades Careers

November 20, 2019

Are you thinking about a new career? Whether you’re just out of school or you’re thinking of switching paths, you may want to consider a career in the trades.

Canada is currently facing a shortage of skilled trades people. Despite offering an opportunity to enjoy a high standard of living, trades careers aren’t attracting enough new professionals to meet demand. This is mainly due to outdated stereotypes about “blue collar” jobs, such as them being low-paid or unsatisfying. But forget what you think you know about the trades! Surveys of people in the construction trades, for example, finds that they are happier in their careers than other Canadians.

And pursuing a career in the trades doesn’t mean you have to give up a great pay cheque for the sake of your passion. Trades people also earn impressively high salaries. After finishing electrician training, for example, you could eventually make over $63,000, which is the average salary for electricians in Canada.

Still not convinced that a career in the trades is a great idea? Check out this infographic about 4 awesome benefits of a trades career.

4 Awesome Benefits of Trades Careers

1. Trades Careers Are Hands-On

Not too keen about sitting behind a computer all day?

Trades careers allow you to work with your hands every day

Build things you can be proud of

Tackle new and exciting challenges

Trades careers involve working in a variety of interesting settings

2. Trades Workers Are In Demand

Canada is facing a skilled labour shortage

The construction industry alone will have 44,100 unfilled job vacancies by 2028

Unfilled industrial maintenance jobs are expected to be almost as high

In Ontario, 91,100 construction workers will retire by 2028

Only 77,800 new entrants will be available to replace them

If you want a job that is in extremely high demand, join the trades!

3. Trades Careers Pay Well

Think a career in the trades doesn’t pay well? Think again!

A shortage of trades workers has fueled impressive wage growth

Check out these average Canadian salaries for in-demand trades:

- Electrician: $63,236

- Plumber: $63,345

- HVAC Mechanic: $58,500

- Roofer: $56,550

- Carpenter: $52,296

- Welding: $50,700

In the trades, experience counts:

Experienced trades workers on average make up to $91,163 per year

4. Earn While You Learn

Don’t want to wait through 4 years of schooling before making money?

Pre-apprenticeship programs take less time to complete!

Once you become a trades apprentice, you’ll earn while you learn

Apprentices work under the supervision of a certified tradesperson

There are so many reasons to pursue a career in the trades!

Discover which option would best suit your interests.

Sources:

https://www.ontario.ca/page/start-apprenticeship

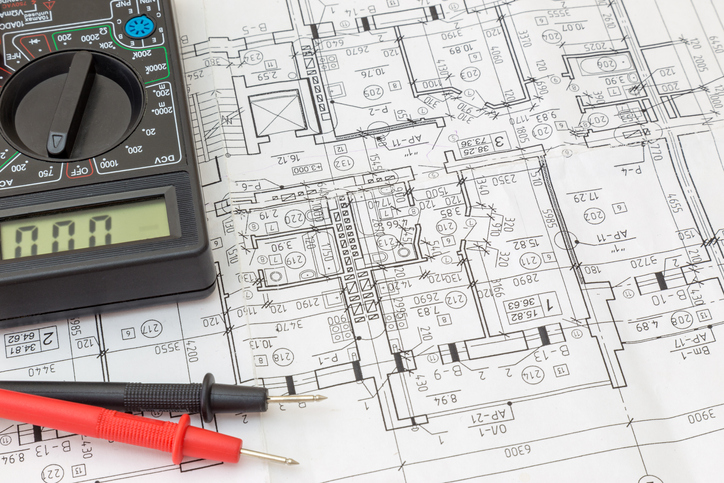

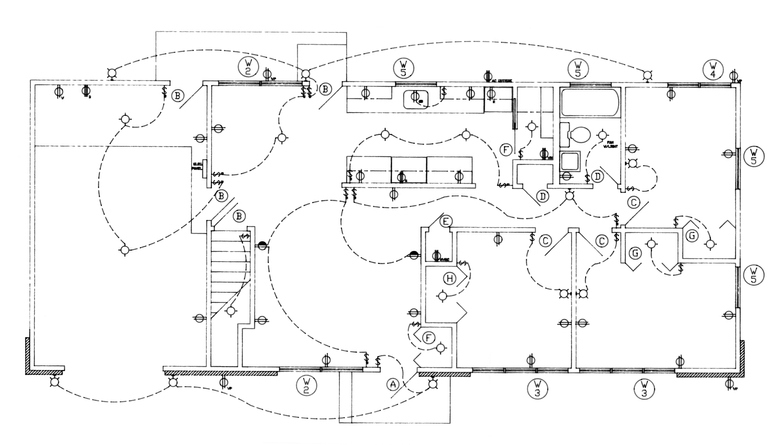

What Electrician Diploma Students Should Know About Reading Layouts

October 08, 2019

As an electrician (particularly a construction electrician), it’s important to be able to understand how to read electrical blueprints or layouts. With these layouts, you will have a better understanding of how electrical systems are to be built, and where all the various parts (eg. light fixtures, switches, wires) need to go. That said, they can be a bit complicated to look through at first. Luckily, it’s easier to get the hang of than you might think.

Regardless of all the symbols and more specialized aspects you may encounter while reading them, there are ways you can effectively interpret an electrical plan without too much trouble. Here’s what you should know about reading layouts if you’re studying to become an electrician.

Read What’s in the Architectural Layout Before the Electrical One

When you look at the floorplan for the building’s architectural layout first, you’ll get a good sense of how much space you have to work with, where things are, and where electrical parts should logically go. Not only that, but you’ll have information about the layout that isn’t necessarily in the electrical portion of the plan. This can help you identify potential conflicts between the architectural and electrical plans that you may not have noticed by only looking at the electrical plan. Either way, you’re going to need to understand what sort of parameters and space you have to work with, since you’ll have to work within them to make sure all the wires are in the right place and able to deliver power throughout the building in ways that are safe for everyone and compliant with bylaws and regulations.

Familiarize Yourself With the Wiring Diagrams and Symbol Legend Before Getting Started

In many electrical layouts, there will be symbols representing various parts, and it’s important to study the symbol legend before you start working. Once you understand the symbols legend, you’ll be able to work faster and more efficiently. The legend will help you understand what the symbols are, what they mean, and where various components need to be. The plans for the project’s electrical components will also likely show diagrams of the paths the wires will take between the different pieces of equipment—important to keep in mind since you will be learning about residential wiring in your maintenance electrician training. This will show you the breakers running each wire, as well as which items within the house (eg. lights) are grouped or phased together onto one breaker.

Your Electrician Training Will Help You to Read Blueprints

All instructions of the electrical layout have to be followed exactly as written—or drawn—and sometimes the information presented can be overwhelming and will require specialized knowledge on electrical components. For example, you’ll need to understand how power across lines will be distributed, as well as the circuit’s flow and critical points where separate wires connect. It sounds like a lot to take in, but it is important information to remember so that the job is done effectively and so that fire, sparks or other hazards can be avoided. Fortunately, in electrician training you will learn how to read blueprints and building layouts, as well as the fundamental principles of electricity. At the end of the day, no part of the layout can be misinterpreted or ignored, and learning about plans and layouts will help you become a better electrician.

Want to get your electrician diploma?

Contact North American Trade Schools to find out more!